1

00:00:03,366 --> 00:00:06,600

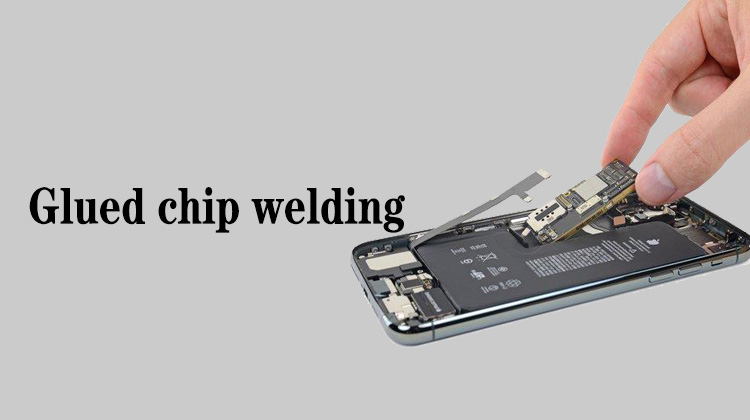

After the chip is removed, we will scrape the glue

2

00:00:11,066 --> 00:00:14,933

I just checked the chip, there is basically no glue left on it

3

00:00:15,533 --> 00:00:17,433

The glue is mainly on the motherboard

4

00:00:18,200 --> 00:00:20,533

Now let's start scraping the glue on the motherboard

5

00:00:21,366 --> 00:00:24,833

Due to the size of the hard disk chip is relatively large

6

00:00:25,433 --> 00:00:27,533

It has a larger space to operate

7

00:00:27,833 --> 00:00:32,666

When we flatten the solder, it is not easy to stick to the surrounding components

8

00:00:33,033 --> 00:00:36,833

So we can apply low melt solder directly to the middle of the pad

9

00:00:40,866 --> 00:00:43,900

Use a soldering iron to melt the low melt solder

10

00:00:47,633 --> 00:00:50,033

Make every pad round and bright

11

00:00:53,333 --> 00:00:56,833

It means that it is completely neutralized with low melt solder

12

00:01:22,733 --> 00:01:26,966

After the low melt solder is applied, we will start to scrape the glue

13

00:01:29,500 --> 00:01:31,900

Rotary-air hot gun for glue scrapping

14

00:01:31,900 --> 00:01:33,766

About 230 degrees

15

00:01:34,200 --> 00:01:36,833

The air volume is still level 3-4

16

00:01:37,166 --> 00:01:39,533

The same temperature as chip reballing

17

00:01:40,800 --> 00:01:43,433

Then the air gun starts to heat the middle area

18

00:01:44,066 --> 00:01:45,300

Obeserve this pad

19

00:01:46,033 --> 00:01:48,166

The surface of the pad is now matte

20

00:01:49,500 --> 00:01:51,433

Reflection is not very strong

21

00:01:51,633 --> 00:01:55,633

The pads will be particularly bright when blown to a certain temperature

22

00:01:56,133 --> 00:01:57,500

Very reflective

23

00:01:58,166 --> 00:02:01,233

That means the solder has been melted and we start to scrape

24

00:02:02,400 --> 00:02:03,533

Don't in a rush

25

00:02:03,900 --> 00:02:05,033

Now it's lit up

26

00:02:06,566 --> 00:02:07,700

The solder melts

27

00:02:08,933 --> 00:02:12,133

Then lay the blade flat on the motherboard and flatten it back

28

00:02:14,533 --> 00:02:16,266

Scrape it off like this

29

00:02:16,700 --> 00:02:17,566

Don't shovel

30

00:02:18,733 --> 00:02:20,533

Don't cut it at an angle

31

00:02:22,166 --> 00:02:24,166

It is easy to scratch the motherboard

32

00:02:24,600 --> 00:02:27,766

We just lay the blade flat and flatten it to the back

33

00:02:43,233 --> 00:02:47,466

To keep turning the angle of the fixture so that we can operate easily

34

00:02:54,833 --> 00:02:58,933

After all the glue has been scraped off, remove the air gun

35

00:02:59,500 --> 00:03:02,133

Because low melt solder solidifies slowly

36

00:03:02,666 --> 00:03:07,333

So we're going to sweep the blade back and forth while the solder isn't solidifying yet

37

00:03:07,500 --> 00:03:10,133

Take away the excess glue and the excess solder

38

00:03:12,100 --> 00:03:14,966

Now it's solidified, let's blow it a little more

39

00:03:16,533 --> 00:03:19,400

This will save you trouble when we flatten the solder

40

00:03:19,800 --> 00:03:21,600

And it's not that difficult to clean

41

00:03:23,933 --> 00:03:24,900

Look at the blade

42

00:03:26,733 --> 00:03:28,633

A big lump of this glue on it

43

00:03:29,500 --> 00:03:30,766

It's easier to clean

44

00:03:33,100 --> 00:03:37,700

When there is a lot of glue on the blade, scrape it onto the motherboard fixture

45

00:03:39,033 --> 00:03:40,300

We're done with the glue