1

00:00:03,000 --> 00:00:05,866

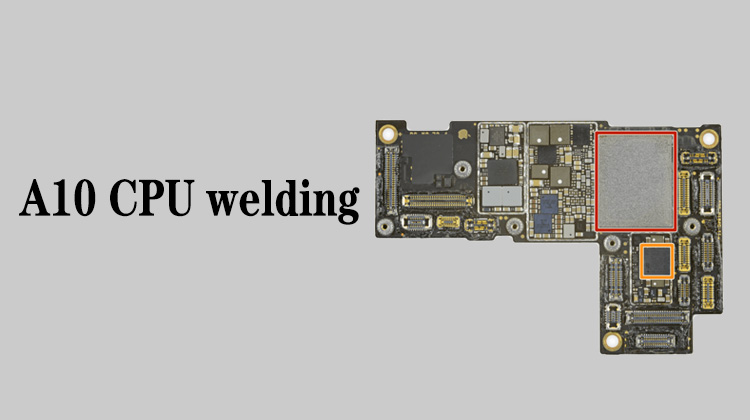

After the dissassembly, let's look at the pads

2

00:00:08,266 --> 00:00:10,466

Check if there are some pads are off

3

00:00:11,566 --> 00:00:13,733

Especially those pins on the edge

4

00:00:14,633 --> 00:00:18,900

Pay attention to these pads where the surface is relatively flat

5

00:00:22,733 --> 00:00:25,200

to see if there is any pads break-off

6

00:00:25,433 --> 00:00:29,900

If the pads break off, there will be a layer of bright yellow on the surface

7

00:00:30,133 --> 00:00:32,433

It is the pin ripped from the CPU

8

00:00:35,466 --> 00:00:38,300

The surface we see now is silvery white,

9

00:00:38,366 --> 00:00:39,366

it doesn't matter

10

00:00:40,233 --> 00:00:42,233

Although some individual pads did not melt

11

00:00:43,300 --> 00:00:47,033

But this is tin, it didn't stick the pads off

12

00:00:47,300 --> 00:00:49,966

We focus on the upper and lower sides

13

00:00:51,566 --> 00:00:56,300

The tin on the top side is all melted so it couldn't fall off a bit

14

00:00:58,666 --> 00:01:01,500

There is a pad break-off, in the middle area

15

00:01:10,100 --> 00:01:14,200

This is basically because the CPU has been dropped before

16

00:01:24,033 --> 00:01:29,866

Pad break-off is generally because you go to pry the CPU while the tin has not melted

17

00:01:30,666 --> 00:01:35,466

As can be clearly seen in this area, the solder has completely melted

18

00:01:35,700 --> 00:01:39,400

And this solder, it is not particularly flat,

19

00:01:40,000 --> 00:01:42,766

The tin in this area has also melted

20

00:01:43,000 --> 00:01:44,900

it is a little convex

21

00:01:45,266 --> 00:01:49,733

This kind of pad is a little loose before we disassemble the CPU

22

00:01:52,633 --> 00:01:55,766

This area of the corresponding CPU can also be seen,

23

00:01:56,900 --> 00:01:59,300

there are several pads break-off

24

00:02:02,600 --> 00:02:06,233

You can't see clearly because it was stabbed by a knife

25

00:02:09,533 --> 00:02:14,000

There are 3 pads break-off here and 2 here

26

00:02:14,233 --> 00:02:17,200

So there are total 5 pads break-off

27

00:02:20,666 --> 00:02:24,800

In this area, pad break-off will continue when we go to scrape

28

00:02:25,066 --> 00:02:28,900

Because this area fell before it was disassembled

29

00:02:29,866 --> 00:02:34,966

Or there is some kind of pulling force on the board that pulls the pad away

30

00:02:40,633 --> 00:02:45,700

In this case, we need to apply the green oil before scraping the glue,

31

00:02:50,233 --> 00:02:53,066

Prevent the tin from getting on when scrapin

32

00:02:54,533 --> 00:02:58,566

Let's clean it first before we apply the green oil

33

00:03:18,733 --> 00:03:22,266

I washed it a little, and the other pads broke off

34

00:03:24,466 --> 00:03:27,866

Now there are total 8 pads break-off

35

00:03:34,200 --> 00:03:40,500

So this pappened because it had a heavy fall, pads would easily break off when we touch it

36

00:03:42,800 --> 00:03:49,333

as for this kind of CPU, when we need to move board, most of them are to be polished

37

00:03:49,900 --> 00:03:55,733

Turn the pcb over, punch it through, and hit the areas where solders are

38

00:03:57,000 --> 00:04:01,433

After that, just bring it over, and clean up the glue on the side a little.

39

00:04:01,700 --> 00:04:05,466

Directly reball, and then install it on the motherboard

40

00:04:05,600 --> 00:04:08,766

As you can see, there are some pads break-off here

41

00:04:08,966 --> 00:04:12,666

But some pads wouldn't break off when they are just a little loose

42

00:04:12,733 --> 00:04:16,733

There is some glue on this side, if we pry it directly,

43

00:04:17,033 --> 00:04:18,733

it will easily break off

44

00:04:19,100 --> 00:04:22,300

This is the case for all CPUs after A10

45

00:04:22,466 --> 00:04:25,366

These pads are particularly fragile

46

00:04:25,700 --> 00:04:31,233

As long as the blowing temperature is enough, if the pads break-off still happen

47

00:04:31,466 --> 00:04:33,733

it has nothing to do with our technique

48

00:04:33,900 --> 00:04:37,866

Whether the temperature is enough mainly depends on the pads

49

00:04:39,633 --> 00:04:41,133

If the pads are flat

50

00:04:41,300 --> 00:04:43,733

like these, or these

51

00:04:46,866 --> 00:04:52,166

This kind is relatively flat, and pad break-off next to it or itself.

52

00:04:52,533 --> 00:04:56,633

That is because the temperature of our disassembly is not enough

53

00:04:57,266 --> 00:05:01,800

But like this area, obviously the pad around him has melted

54

00:05:02,900 --> 00:05:06,466

If the pads break off again, it's not because of the temperature.

55

00:05:11,966 --> 00:05:16,366

Now let's use the curing light to cure it after we finish the green oil

56

00:05:42,433 --> 00:05:45,900

Now, the CPU pad break-off preprocessing is finished