1

00:00:02,600 --> 00:00:05,533

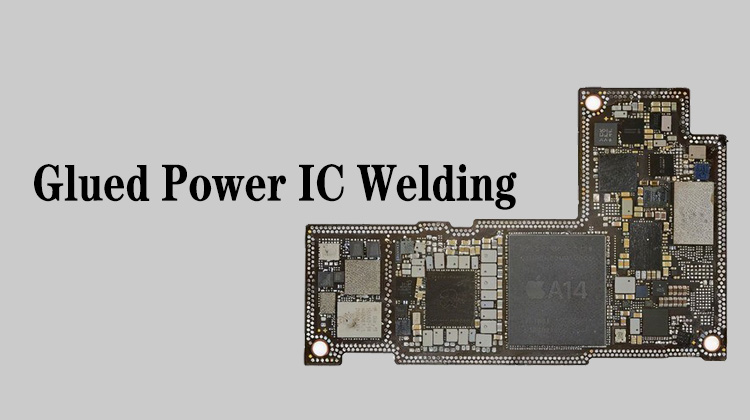

Next, let's deal with the pads of the mainboard

2

00:00:09,066 --> 00:00:12,733

There are more dirty things on the edge, so don't rush to flatten it

3

00:00:12,933 --> 00:00:15,100

First clean up this residue or something

4

00:00:17,200 --> 00:00:21,100

Otherwise, after flattening, the residue will be more difficult to clean

5

00:00:36,466 --> 00:00:38,666

Put some soldering oil on the mainboard

6

00:00:47,466 --> 00:00:50,933

Use the solder wick to smooth all the soldering tin on the pads

7

00:01:16,000 --> 00:01:18,333

When flattening, the force must be light

8

00:01:59,366 --> 00:02:02,700

the big, unmovable spots like this one on the edge

9

00:02:02,700 --> 00:02:06,633

appeared when the low melt solder is not completely flattened through

10

00:02:07,066 --> 00:02:10,733

Dip some low melt solder on the soldering iron and flatten again

11

00:02:50,766 --> 00:02:54,466

Because there is a lot of glue residue at the very edge at the beginning

12

00:02:54,766 --> 00:02:58,066

When we flattened, some pads were separated by the glue

13

00:02:58,800 --> 00:03:01,066

The soldering iron is not easy to reach it

14

00:03:02,600 --> 00:03:04,866

So after this edge glue is processed,

15

00:03:05,233 --> 00:03:08,600

if the surrounding tin is not clean, we will flatten it again

16

00:03:22,933 --> 00:03:26,900

At this time, take the solder wick to absorb it, it will be easier to melt

17

00:04:10,966 --> 00:04:14,766

Okay, after all the pads have been flattened, let's clean it up

18

00:04:38,733 --> 00:04:40,933

Let's clean up the solder residue around

19

00:04:41,133 --> 00:04:44,866

Because when the glue is removed and then the low melt solder is applied,

20

00:04:45,200 --> 00:04:47,066

there will be some small residues.

21

00:04:47,400 --> 00:04:50,200

We're going to clean it up to prevent a short circuit

22

00:04:51,400 --> 00:04:52,533

it is now active

23

00:04:52,766 --> 00:04:56,200

But once heated, it may stick to the middle of the components

24

00:04:56,833 --> 00:04:58,900

It doesn't matter much like this position

25

00:04:59,100 --> 00:05:02,266

But there must be no tin paste on the top side just now.

26

00:05:18,466 --> 00:05:20,500

Take a look at the position of the copper leak

27

00:05:21,400 --> 00:05:25,800

If the copper leakage is a little more serious, we need to put a little green oil

28

00:05:26,433 --> 00:05:28,033

Like this, it doesn't really matter,

29

00:05:28,200 --> 00:05:30,066

because it's far away from the edge

30

00:05:32,833 --> 00:05:35,633

There is also a little copper leakage on this corner,

31

00:05:35,866 --> 00:05:37,100

but it doesn't matter.

32

00:05:40,833 --> 00:05:42,600

We have already dealt with the pads